UV Lining: An Innovative Method for Trenchless Pipe Rehabilitation

- Layla Tong

- Apr 1, 2025

- 2 min read

UV lining, also known as UV-cured pipe lining or UV-cured CIPP (Cured-In-Place Pipe), is an innovative method for trenchless pipe rehabilitation. This technique is particularly effective for repairing damaged or deteriorated sewer and drain pipes without the need for excavation.

How UV Lining Works

Inspection:

The process begins with a thorough inspection of the sewer or drain pipe using CCTV cameras. This step assesses the condition of the pipe and identifies any defects, cracks, or blockages.

Preparation:

The pipe undergoes meticulous cleaning to eliminate debris, roots, and buildup that could hinder the lining process. High-pressure water jetting or mechanical cleaning tools are typically employed for this purpose.

Measurements:

Accurate measurements of the pipe's length and diameter are taken to ensure the lining material fits perfectly.

Lining Installation:

A flexible lining material, usually a felt or fiberglass tube coated with resin, is inserted into the damaged pipe using inversion or pull-in techniques. This lining is positioned to thoroughly cover the affected areas. Once in place, the lining is inflated with air or water pressure to ensure it conforms tightly to the interior of the host pipe.

UV Curing:

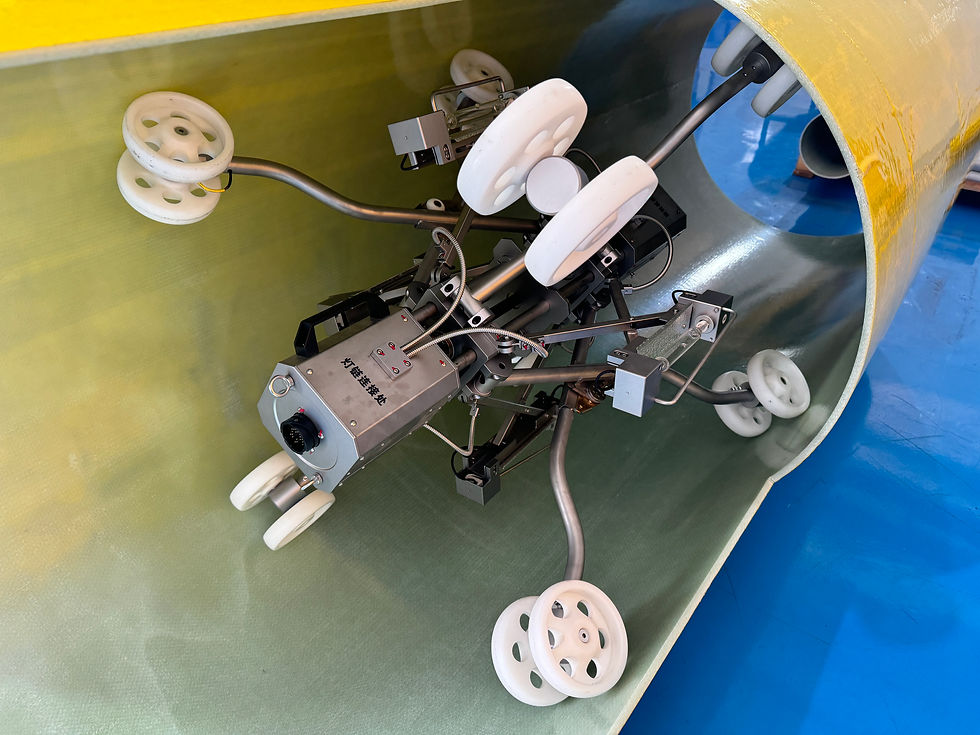

After proper positioning, UV light is utilized to cure (harden) the resin. This is achieved with UV light-emitting panels or trains that are inserted into the lined pipe. The UV light activates photoinitiators in the resin, causing it to polymerize and form a solid, durable lining within minutes.

Quality Control:

Throughout the curing process, critical parameters such as pressure, temperature, and curing time are meticulously monitored to ensure optimal curing and adhesion of the lining material to the host pipe.

Final Inspection:

Once curing is complete, a final inspection using CCTV cameras is conducted to verify the integrity of the newly rehabilitated pipe and confirm that no defects remain.

Advantages of UV Lining

UV lining offers several significant advantages over traditional pipe repair methods:

Minimal Disruption: As excavation is not required, UV lining minimizes disruption to the surrounding environment, traffic, and landscaping.

Speed: The rapid curing times associated with UV technology enable quick turnaround for pipe rehabilitation projects.

Longevity: UV-cured liners create a seamless, jointless, and corrosion-resistant pipe within the host pipe, significantly extending its lifespan.

Cost-effectiveness: Although the initial costs of UV lining may be higher than traditional methods, it often results in long-term savings due to reduced labor, equipment, and restoration expenses linked to excavation.

Overall, UV CIPP lining stands out as a versatile and efficient solution for trenchless rehabilitation of damaged sewer and drain pipes, delivering durable and long-lasting repairs with minimal disruption.

As you consider the benefits of this technology, it's worth noting that Anyue is a leading manufacturer of high-quality UV CIPP liners and advanced equipment, expertly designed for effective trenchless pipe repair.

Comments